MVR , short for Mechanical Vapor Recompression, is an advanced and energy-saving technology which uses the latent heat of the secondary steam produced during evaporation, so as to reduce the live steam consumption.

MVR principle: After compressing by a vapor recompressor, secondary steam with higher temperature, pressure and enthalpy is used to heat the evaporation system. Therefore, the thermal efficiency of the whole evaporation system is enhanced as the steam condensate as well as the latent heat of the waste vapor can both be reused.

MVR Process: The MVRprocess combines evaporation technology with heat pump technology. Through the heat pump (mechanical vapor compressor), the electrical energy is first converted into mechanical energy; and the mechanical energy will then be converted into heat, which is used to compress the secondary steam of low grade into the one of high grade. The steam of high grade will be used as the heating steam to keeping the product boiling at the heating chamber of the evaporator, and the heating steam will become water by condensation.

The heat energy required for evaporation comes from the heat energy released by vapor condensation and condensate cooling. It also means that the energy required for the evaporation process is only the electrical energy consumed by the heat pump (mechanical vapor compressor), other pumps and the controlling system.

The live steam is only required for start-up. The whole evaporation process will not need any live steam after entering normal operation stage (a small amount of live steam will be required where the feed conditions fluctuate).

Features of MVR process:

• High thermal efficiency and low running cost, the energy consumed by a MVR is only 1/3 to 1/7 of the one consumed by a conventional five-effect evaporator.

• Clean energy, without any pollution. AS MVR evaporators are electrical driven, no CO2 and SO2 will be generated. No cooling water is required.

• By recovering the secondary steam, the content of COD and BOD of the steam condensate are much lower than the ones of conventional multi-effect evaporators, and completely in conformity with national emission standards

• As upgrade products of conventional multi-effect falling film evaporators, technically speaking, conventional multi-effect film evaporators can be completely replaced by MVR evaporators. What’s more, the latter is much more environmentally friendly and energy-saving than the former.

• Highly automated; With IPC and DCS (or PLC) control system and frequency conversion technology, MVR evaporators are able to operate fully automatically without watch-keeper.

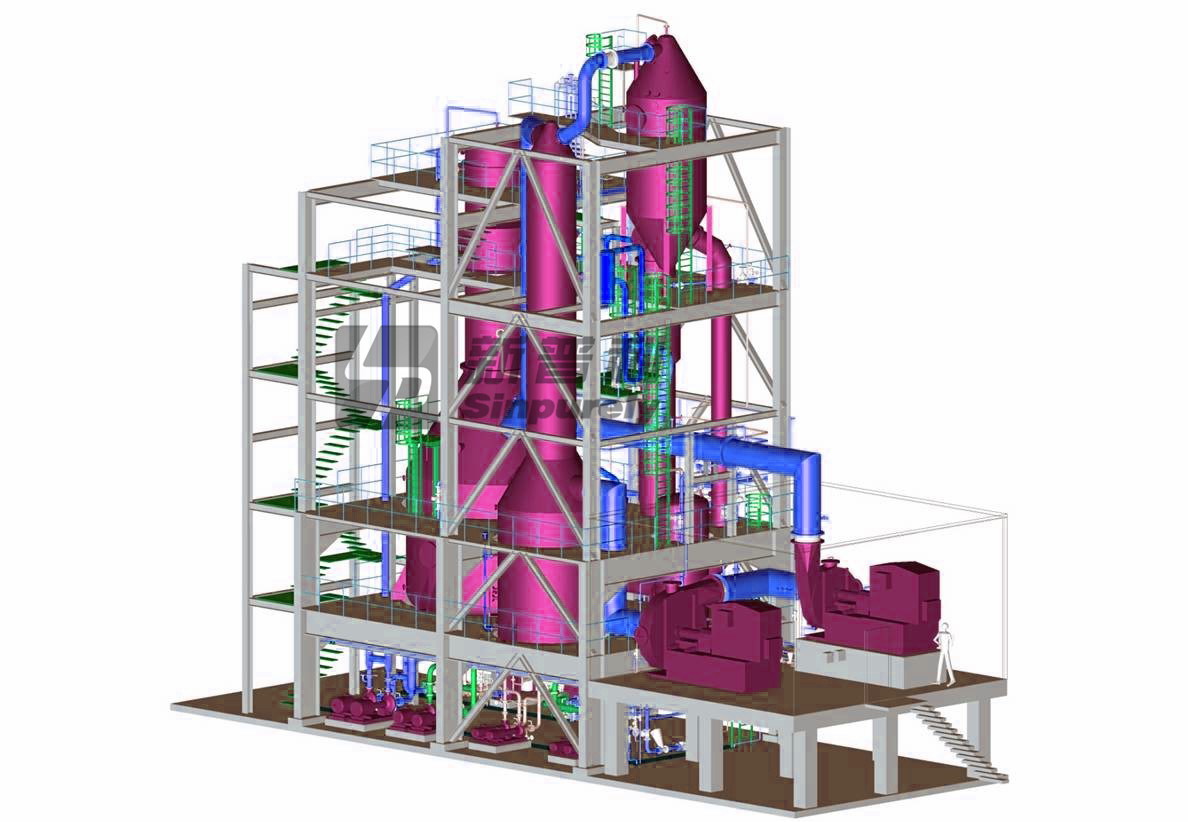

• Small covering area, an evaporator of small or medium size only covers 10 to 50 m2; Moreover, they can also be designed to mobile structure, making them easy to be installed, adjusted and moved.